Waste Water Treatment Using Proprietary Water Processing Technology

Introduction

Introducing a novel technology that can;

Background

Drinking water, also known as potable water or improved drinking water is considered safe enough for drinking and food preparation.

Globally, in 2012, 89% of people had access to water suitable for drinking.

Nearly 4 billion had access to tap water while another 2.3 billion had access to wells or public taps.

1.8 billion people still use an unsafe drinking water source which may be contaminated by feces. This can result in infectious diarrhea such as cholera and typhoid among others.

Throughout most of the world today, the most common contamination of raw water sources is from human sewage and in particular human fecal pathogens and parasites.

In 2006, waterborne diseases were estimated to cause 1.8 million deaths each year while about 1.1 billion people lacked proper drinking water.

Introduction

Introducing a novel technology that can;

- “transform” contaminated, polluted, and even environmentally toxic water into an easier to handle, higher quality water,

- reducing or eliminating

- heavy metals

- trace organic compounds

- total suspended solids (TSS)

- turbidity

- Micro-biological’s including Coliform bacteria, E. coli, specific pathogenic species of bacteria (such as cholera-causing Vibrio cholerae), viruses, and protozoan parasites.

Background

Drinking water, also known as potable water or improved drinking water is considered safe enough for drinking and food preparation.

Globally, in 2012, 89% of people had access to water suitable for drinking.

Nearly 4 billion had access to tap water while another 2.3 billion had access to wells or public taps.

1.8 billion people still use an unsafe drinking water source which may be contaminated by feces. This can result in infectious diarrhea such as cholera and typhoid among others.

Throughout most of the world today, the most common contamination of raw water sources is from human sewage and in particular human fecal pathogens and parasites.

In 2006, waterborne diseases were estimated to cause 1.8 million deaths each year while about 1.1 billion people lacked proper drinking water.

Most water requires some type of treatment before use, even water from deep wells or springs. The extent of treatment depends on the source of the water. Tap Water, the water we consume IS chemically treated water. Treated water comes from these very Water Treatment Plants. In cities and towns around the world this water is recycled over and recycled over again and again for our consumption and use. In the U.S., the typical single family home consumes 69.3 gallons (262 litres) of water per day. Uses include (in decreasing order) toilets, washing machines, showers, baths, faucets, and leaks.

This water makes only a portion of the wastewater we create. While the composition of Wastewater varies widely, this is a partial list of what it may contain:

Understandably, these constituents put tremendous loads on our current wastewater and water treatment facilities.

Around 90% of wastewater produced globally remains untreated, causing widespread water pollution, especially in low-income countries. The vast majority of the agricultural products consumed in the United States come from these low-income countries. Because agriculture has to compete for increasingly scarce water resources with industry and municipal users in these areas, there is often no alternative for farmers but to use water polluted with urban waste directly to water their crops.

The health risks of polluted irrigation water

There can be significant health hazards related to using untreated wastewater in agriculture. Wastewater from cities can contain a mixture of chemical and biological pollutants. In low-income countries, there are often high levels of pathogens from excreta, while in emerging nations, where industrial development is outpacing environmental regulation, there are increasing risks from inorganic and organic chemicals.

This water makes only a portion of the wastewater we create. While the composition of Wastewater varies widely, this is a partial list of what it may contain:

- Water (more than 95 percent), which is often added during flushing to carry waste down a drain;

- Pathogens such as bacteria, viruses, prions and parasitic worms;

- Non-pathogenic bacteria;

- Organic particles such as feces, hairs, food, vomit, paper fibers, plant material, humus, etc.;

- Soluble organic material such as urea, fruit sugars, soluble proteins, etc.;

- Inorganic particles such as sand, grit, metal particles, ceramics, etc.;

- Soluble inorganic material such as, heavy metal salts, ammonia, bleach (hypochlorite’s/etc.), phosphates, road-salt, sea-salt, cyanide, hydrogen sulfide, thiocyanates, thiosulfates, etc.;

- Animals such as protozoa, insects, arthropods, small fish, etc.;

- Macro-solids such as sanitary napkins, nappies/diapers, condoms, needles, children's toys, dead animals or plants, etc.;

- Gases such as hydrogen sulfide, carbon dioxide, methane, etc.;

- Emulsions such as, cooling oils / greases, paints, adhesives, mayonnaise, hair colorants, emulsified oils, etc.;

- Toxins such as pesticides, poisons, herbicides, etc.

- Pharmaceuticals (drugs and antibiotics), hormones and other hazardous substances

Understandably, these constituents put tremendous loads on our current wastewater and water treatment facilities.

Around 90% of wastewater produced globally remains untreated, causing widespread water pollution, especially in low-income countries. The vast majority of the agricultural products consumed in the United States come from these low-income countries. Because agriculture has to compete for increasingly scarce water resources with industry and municipal users in these areas, there is often no alternative for farmers but to use water polluted with urban waste directly to water their crops.

The health risks of polluted irrigation water

There can be significant health hazards related to using untreated wastewater in agriculture. Wastewater from cities can contain a mixture of chemical and biological pollutants. In low-income countries, there are often high levels of pathogens from excreta, while in emerging nations, where industrial development is outpacing environmental regulation, there are increasing risks from inorganic and organic chemicals.

Treatment

Current State Of The Art

Wastewater and Water Treatment technologies are well-known and applied in a variety of ways, depending on numerous factors, several methods are in use today;

Biological Treatment

Physical / Chemical Treatment

Not surprisingly, each of these processes has their own limitations, advantages and disadvantages. The informed consensus is that a combination of methods needs to be used to meet discharge standards; - and, that activated carbon absorption and Reverse Osmosis (RO) seem to be the best solutions. No coincidence these two methods are the top two in expense and upkeep.

Technologies for potable water treatment are well developed, and generalized designs are available that are used by many water utilities (public or private). In addition, a number of private companies provide patented technological solutions. Automation of water and waste-water treatment is common in the developed world. High Capital costs, increasing operating costs, the availability of quality monitoring technologies and locally available skills typically dictate the level of automation adopted.

Industrial water and wastewater treatment

Two of the main processes of industrial water treatment are boiler water treatment and cooling water treatment. A lack of proper water treatment can lead to the reaction of solids and bacteria within pipe work and boiler housing. Steam boilers can suffer from scale or corrosion when left untreated. Scale deposits can lead to weak and dangerous machinery issues, while additional fuel is required to heat the same level of water because of the rise in thermal resistance/fouling.

OPPORTUNITY

Application

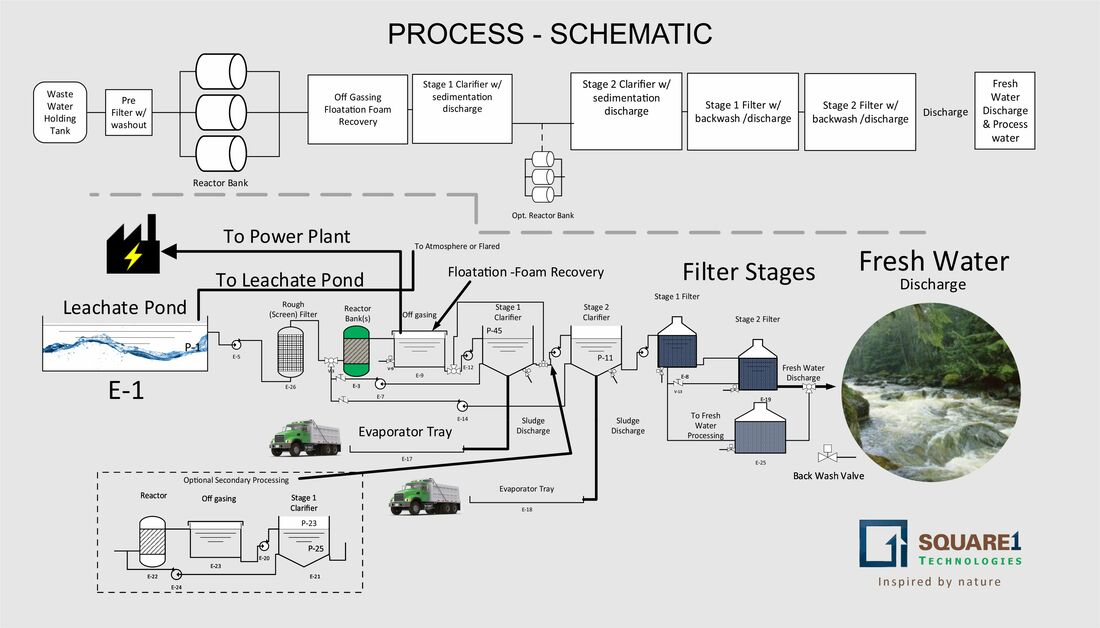

Provide proven technologies, integrated in new and novel ways that can be deployed;

Current State Of The Art

Wastewater and Water Treatment technologies are well-known and applied in a variety of ways, depending on numerous factors, several methods are in use today;

Biological Treatment

- Aerobic Treatment

- Anaerobic Treatment

Physical / Chemical Treatment

- pH Control

- Floatation

- Coagulation

- Adsorption and Absorption

- Membrane Filtration

Not surprisingly, each of these processes has their own limitations, advantages and disadvantages. The informed consensus is that a combination of methods needs to be used to meet discharge standards; - and, that activated carbon absorption and Reverse Osmosis (RO) seem to be the best solutions. No coincidence these two methods are the top two in expense and upkeep.

Technologies for potable water treatment are well developed, and generalized designs are available that are used by many water utilities (public or private). In addition, a number of private companies provide patented technological solutions. Automation of water and waste-water treatment is common in the developed world. High Capital costs, increasing operating costs, the availability of quality monitoring technologies and locally available skills typically dictate the level of automation adopted.

Industrial water and wastewater treatment

Two of the main processes of industrial water treatment are boiler water treatment and cooling water treatment. A lack of proper water treatment can lead to the reaction of solids and bacteria within pipe work and boiler housing. Steam boilers can suffer from scale or corrosion when left untreated. Scale deposits can lead to weak and dangerous machinery issues, while additional fuel is required to heat the same level of water because of the rise in thermal resistance/fouling.

OPPORTUNITY

Application

Provide proven technologies, integrated in new and novel ways that can be deployed;

- At the Industrial Point-of-Use or

- Point of Discharge or

- as a stand-alone solution or

- in conjunction with the existing technological processes of Wastewater and Water Treatment.

- No Chemical Additives

- No Polyelectrolytes Additives

- No Bacterial Additives

- Active technology able to remove chemical and biologic agents in one step

- Dramatically reduces or eliminates the load on Industrial or Municipal Wastewater Treatment Plants.

- Provide an economic alternative to industrial water users by enabling the recycling of water within their processes instead of releasing into the wastewater treatment systems.

- Provide an economic alternative agriculturally that is safe for irrigation purposes

- Provide or create an alternative water supply to industry for various processes.

- Lower operating costs

- Cost-effective equipment maintenance.

- Greatly Reduced footprint requirement over conventional methods

- Cost/value basis purchase or lease option -providing shorter ROI

Summary

Utilization of this proprietary technology solution;

Utilization of this proprietary technology solution;

- Reduces or eliminates the load on Municipal Wastewater Treatment Plants

- Reduces or eliminates the use of; Chemical Additives, Polyelectrolytes Additives, Bacterial Additives

- Provides an economic alternative to industrial water users by enabling the recycling of water within their processes before the need releasing into the wastewater treatment systems.

- Greatly Reduces footprint requirement over conventional methods

- Provides shorter ROI via Cost/value basis purchase or lease.